ELPLC S.A. builds a robotic line for the production of electronic chokes

Bartlomiej Juszczyk, Piotr Jaworski, 2023.01.17, Lines & machines

According to the estimates of the Energy Market Agency, the installed capacity of photovoltaics in Poland at the end of November 2022 reached 11.92 GW, which is 54% of the installed RES capacity. Each installation is the right amount of photovoltaic modules and AC-DC inverters. The inverter consists of a number of electronic components depending on the advancement of the structure and additional functions. One of such components is the choke, which, being part of the output circuit, reduces current ripple. The choke is a structure containing cores, coils and additional mounting elements.

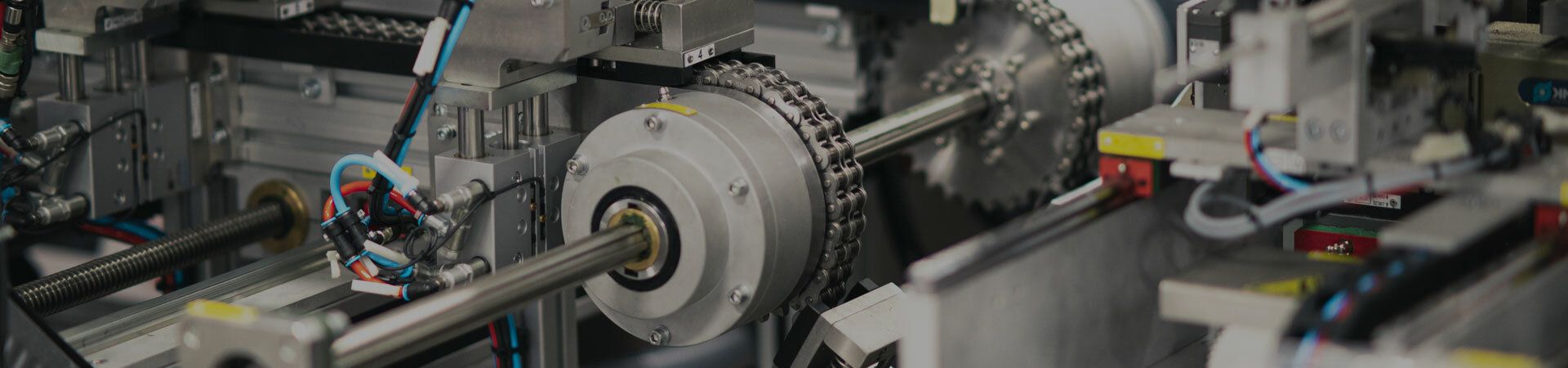

Choke assembly line

ELPLC S.A. builds a choke assembly line for one of the leading European manufacturers. The line is characterized by a high degree of automation, robotization and autonomy, as well as support for many product references. The role of the operator will be limited to refilling the semi-products in the feeders. The mounting sockets have been designed to handle all the references required by the customer without the need for retooling.

Chokes production stages

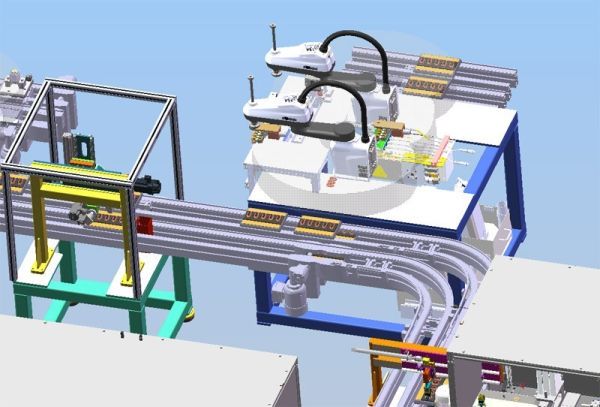

The first stage of production is unrolling and cutting the wire to size. Then its ends are milled and the coil is formed. The next stage of production is soldering of the terminals in a nitrogen shield and visual quality control. Loading of finished coils to the main assembly line and internal reloading from pallet buffers is performed by OMRON fast SCARA robots.

The main assembly line consists of 12 stations connected by a pallet conveyor. The RFID system ensures product tracking in the process. Vibrating feeders deliver semi-finished products for the assembly process:

- spring plates,

- cores,

- segers,

- lid and carcass,

- coils in the number resulting from the models of selected packages.

After packaging, the robot transfers the product to the rotary welding cell, which ensures the possibility of double-sided welding. Vision control, electrical tests of initial inductance and voltage strength are used to check the quality of the product. The laser marker engraves an alphanumeric symbol on the carcass and the SCARA robot unloads the finished details into collective packaging.

Control System and ELPLC Smart Factory

The control system is based on a Mitsubishi Melsec iQ-R PLC series with additional distributed I/O and servo modules communicating via the CC-Link network. The ELPLC Smart Factory system is responsible for the acquisition of production data. It is a production management and monitoring system that collects data from machines, analyzes them on-line and presents the results in reports that are easy to understand. It consists of two modular applications: Monitoring and Web. It allows you to determine OEE indicators and defined KPIs by analyzing the production flow and micro-stoppages. It provides information to maintenance services enabling early diagnostics of machines - Predictive Maintenance. In addition, data exchange with the customer's internal MES system is ensured.

Large project

The construction of an automatic line for the production of chokes is one of the largest projects of ELPLC S.A. in 2023. It will provide necessary production capacity of an important component for AC-DC inverters.

ELPLC SA machines and lines

We specialize in designing and building machines, complete robotic assembly lines and creating software for the industry. We offer our competences for many industries. We provide Industry 4.0 / Smart Factory solutions.

Automation and robotization

Machines and lines building

Modernization fo existing lines

Software for industry

Service and maintenanace

Research and development

Return to blog

Want to know more? Ask experts