Offer

Full range of services for industry

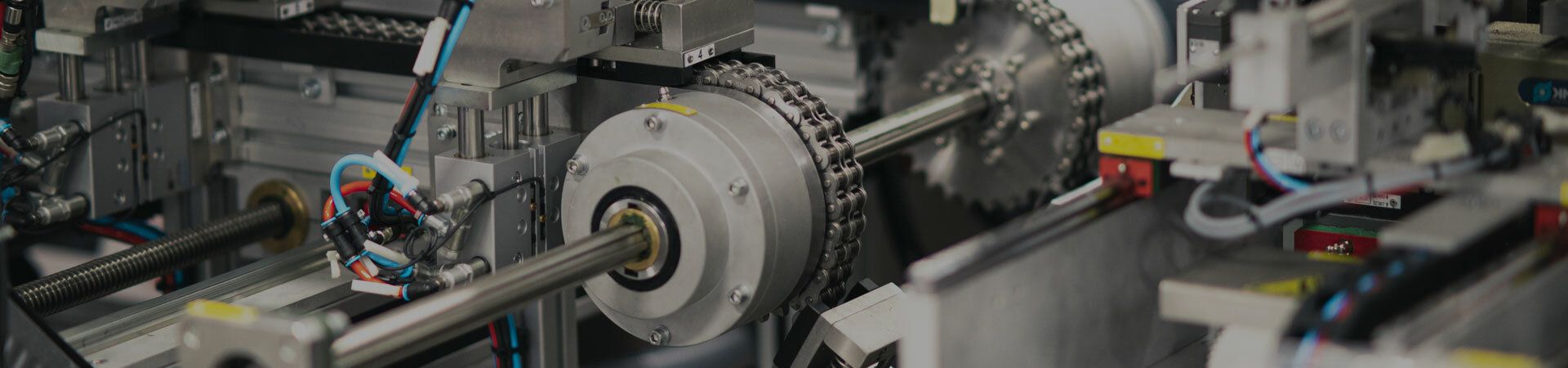

Automation

& robotization

Full range of services in the field of automation and robotization.

Modernization

of existing lines

We offer our experience in modernizing existing lines and machines.

Software

for industry

Software and systems tailored to the needs of the factory environment.

ELPLC manufactures specialized and prototype solutions in the field of automation and robotization of production processes. We specialize in the design and build of machines, complete assembly lines, automated stations and software development for the industry. We offer our solutions for various industries: automotive, e-mobility, renewable energy, metallurgy, ceramics, plastics, construction, chemistry, electronics, electrical engineering and others. We provide solutions in the area of Industry 4.0 - Smart Factory and are a pioneer in the field of industrial solutions using mixed and augmented reality.

ELPLC is a team of almost 200 specialists, including designers, programmers, mechatronics, automation specialists and engineers. We have our own Research and Development Center (ministerial CBR status from 2021) and a modern production infrastructure.

Career

Let's create the Future together!

Are you a specialist?

We are currently looking for specialists for the position:

show me open positionsClients

Who trusted us