Selected Processes on Electronic Device Assembly Lines (1)

Bartlomiej Juszczyk, 2023.07.19, Machine buidling

Read also: Robotic assembly of car lights

The electronics industry employs numerous processes for manufacturing devices. These processes significantly influence the quality and efficiency of production. Automation of these processes allows for cost reduction and minimizes the number of errors. The dynamic advancement of technology and increasing market demands compel electronic device manufacturers to invest in improving assembly processes, enhancing productivity, and reducing the risk of delivering faulty products.

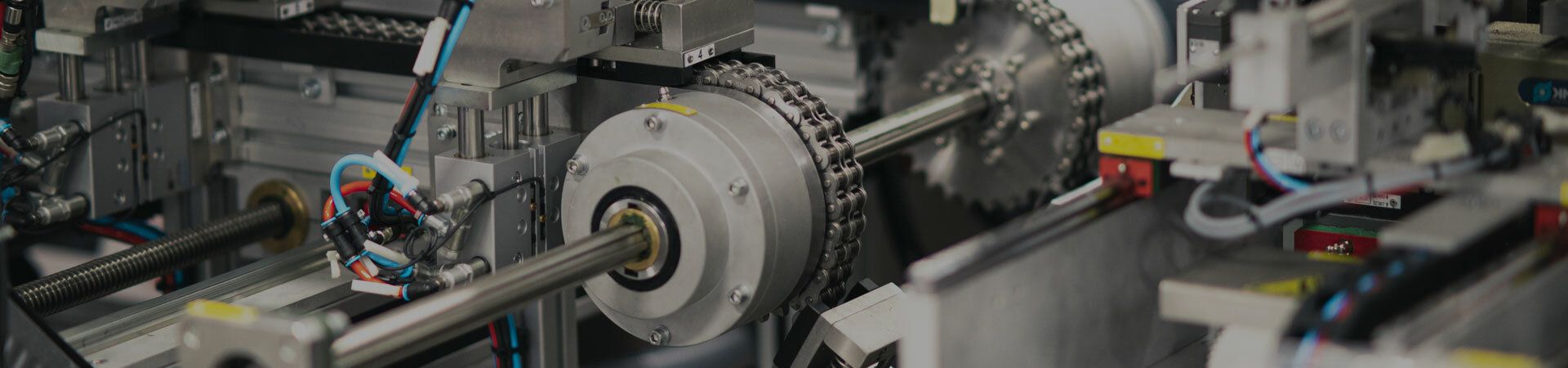

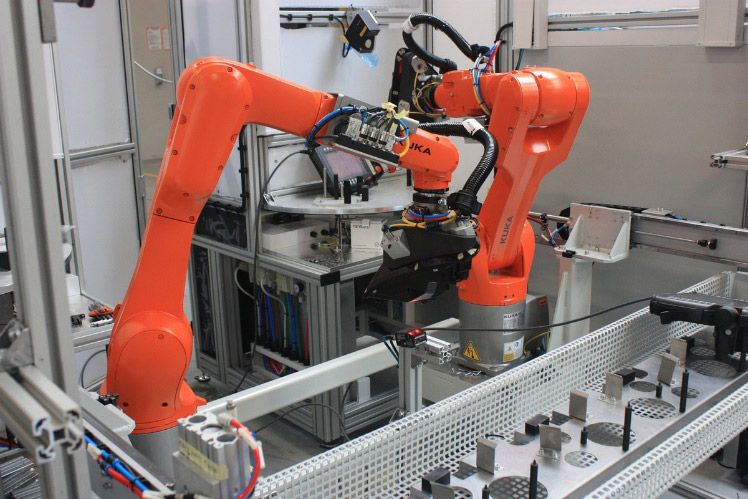

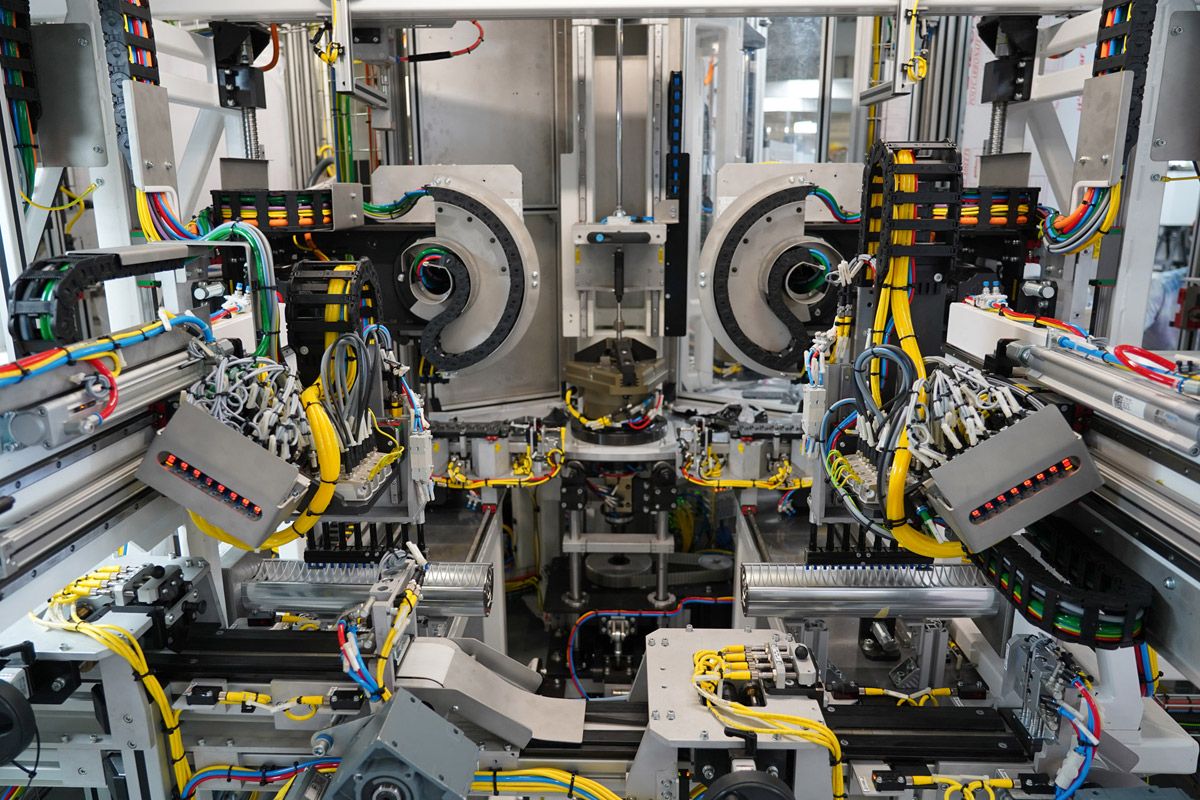

Robotic Mechanical Assembly

The mechanical assembly of modules or devices from semi-finished products is worth automating. Often, these processes involve pick & place operations with assembly ready-made PCBs and additional elements such as washers, seals, or spacer sleeves inside enclosures. SCARA robots are well-suited for such tasks. The advantages of this solution include precision, repeatability, and speed. An appropriately designed robot gripper allows for adaptation to the product type and integration of various operations in a small space. The gripper is equipped with manipulators, vision systems for guidance or verification, as well as screwdrivers and screw-feeding systems. Robotic workstations can be designed to operate independently or in line with a conveyor system. The right number of robotized stations and appropriate pallet transport motion management software enables production optimization over time.

Interested in this topic? Ask the experts

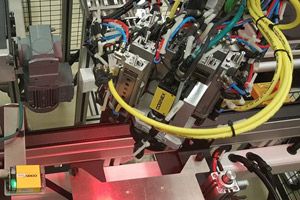

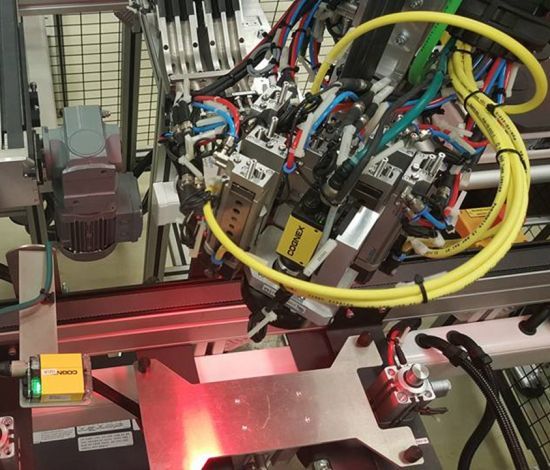

Adhesive and Sealant Application

Depending on the type of components and product purpose, it is necessary to dispense and apply substances with various properties, such as adhesives, sealants, and thermo/electro-conductive compounds. In the assembly line for PTC heaters, a thermally conductive adhesive is dosed with compensation for the actual component position on the pallet. The solution, based on a vision system, servo drive and scale, allows for the correct application of the layer with precision of ±0.0125g and droplet diameter of approximately 1.9mm. The proper glue mixture is ensured by a system of dosing needles with a mixing tube with a constant mixing ratio. Servo-controlled dispensing pistons feed substrates into the mixing tube. The connection is stabilized at the thermal curing station by heating the component to a temperature of around 100-120°C. Another automatic glue application system handles the side walls of the component with dosing precision of ±0.005g.

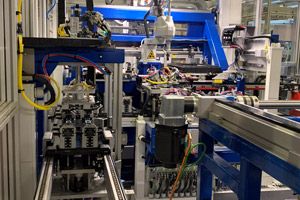

Infrared Welding

Infrared welding is a clean assembly process for plastic components, utilizing a special movable head with a lamp and a reflective inner surface. The head is moved onto a plastic peg, which positions the components to be joined. The reflective interior of the head concentrates the infrared energy from the lamp onto the plastic peg, heating it up. The plastic becomes soft, and a tip presses it, flattening and forming the peg to secure the components.

ELPLC SA machines and lines

We specialize in designing and building machines, complete robotic assembly lines and creating software for the industry. We offer our competences for many industries. We provide Industry 4.0 / Smart Factory solutions.

Automation and robotization

Machines and lines building

Modernization fo existing lines

Software for industry

Service and maintenanace

Research and development

Return to blog

Want to know more? Ask experts