Selected Processes on Electronic Device Assembly Lines (2)

Bartlomiej Juszczyk, 2023.07.19, Machine buidling

Read also: Robotic assembly of car lights

Testing on production lines is no longer merely an optional stage in the production cycle. It has become a pivotal element that influences the quality, reliability, and efficiency of end products. This is a process that enables the detection of potential issues and shortcomings before products reach the hands of customers. To prevent damages and ensure the integrity of electronic components, appropriate measures are also applied for protection against electrostatic discharges (ESD).

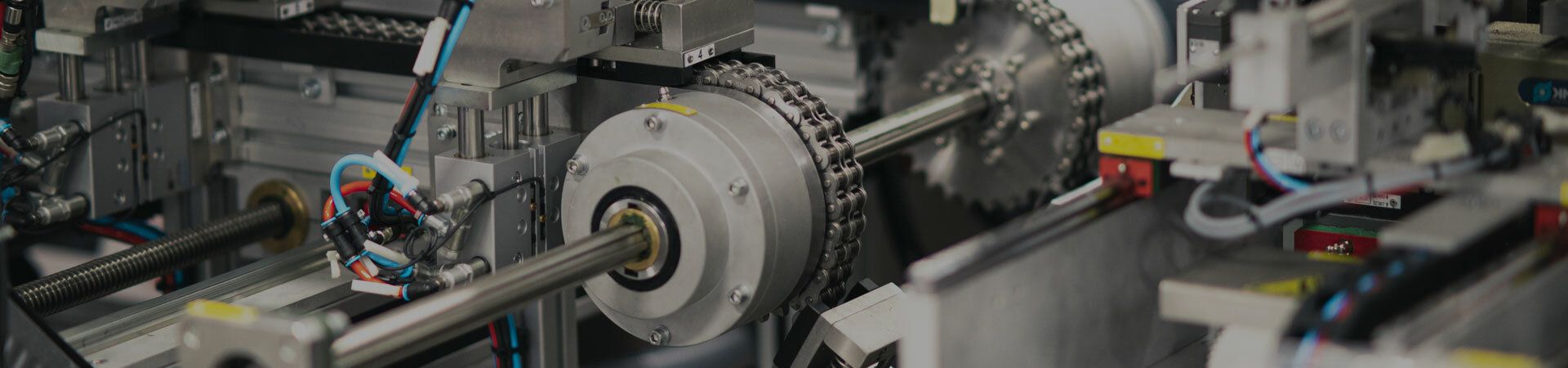

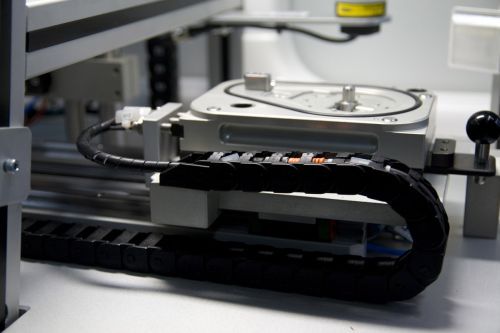

Functional and Electrical Testing

After completing the individual assembly phases, the product or its components undergo testing to ensure proper functionality. Tests may include checking functionality, HiPOT testing, measuring electrical parameters and performance, as well as detecting any defects or damages. Such testers utilize programmable measurement instruments that communicate with the station's PLC or a specifically designed control and measurement ecosystem (e.g., National Instruments).

Interested in this topic? Ask the experts

Enclosure Leak Testing

For devices exposed to adverse external conditions, enclosure integrity testing may be necessary. This test is performed using a station with a suitably fitted socket or a chamber ensuring sealability. The main measuring instrument used is a programmable leak detector that measures leakage using the pressure drop method. Additionally, such a station may be equipped with a marking or code application station and bins or containers for rejected pieces.

ESD Protection

Damages to electronic components and circuits resulting from electrostatic discharges are often noticeable only under an electron microscope. They become apparent either during the initial device start-up or after a relatively short period of operation. For manufacturers, this can result in significant costs associated with warranty service. Therefore, ESD protection guidelines should be followed.

But what exactly is ESD? The acronym stands for "electrostatic discharge" and refers to the sudden flow of electric current between two objects with different electric potentials. Electric potentials are generated by electrification, which can occur through movement or friction in industrial conditions. Even small voltages that do not cause visible discharges can damage sensitive components.

Requirements regarding the implementation of ESD protection are gathered in the DIN EN 61340-5-1 standard. Taking a comprehensive look at the issue requires consideration not only of procedures and measures within the facility but also the selection of suitable suppliers of production lines or machines. The supplier must be aware of the concept of an electrostatic protected area (EPA), which can range from a single station to an entire building. They must also know how to apply protective elements such as grounding strips at stations, antistatic wristbands, grounding cables, mats, antistatic transport systems, chains for intralogistics vehicles, and more.

ELPLC SA machines and lines

We specialize in designing and building machines, complete robotic assembly lines and creating software for the industry. We offer our competences for many industries. We provide Industry 4.0 / Smart Factory solutions.

Automation and robotization

Machines and lines building

Modernization fo existing lines

Software for industry

Service and maintenanace

Research and development

Return to blog

Want to know more? Ask experts