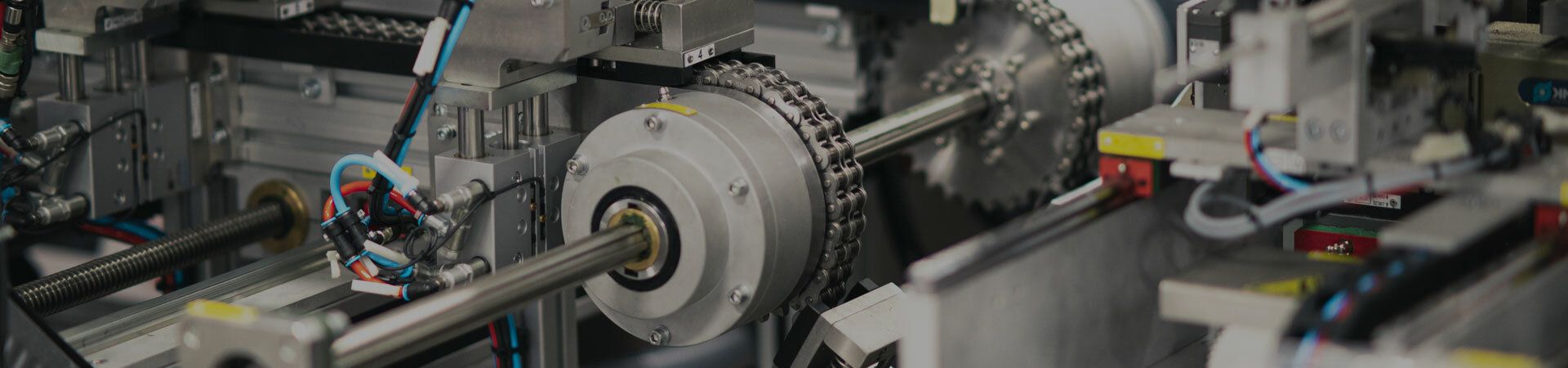

Lines and machinery in the production of automotive air conditioning hoses (1)

Bartłomiej Juszczyk, 2023.05.17, Machine building

Air conditioning in a car is associated with comfortable vehicle use, particularly during the summer. Ensuring its proper functioning requires not only regular servicing but also high-quality components within the system, such as the compressor, evaporator, condenser, and hoses. The air conditioning hoses play a crucial role in maintaining refrigerant circuit tightness and providing adequate pressure and temperature resistance.

A brief overview of refrigerants

Until 2017, the R-134a refrigerant was widely used due to its favorable thermodynamic properties and high auto-ignition temperature (770°C). However, it was discovered that its GWP [1] factor is as high as 1430. As a result, Directive 2006/40/EC was enacted, prohibiting the use of this refrigerant in newly produced vehicles starting from January 1, 2017. R134a has been replaced by the R1234yf refrigerant, which has a GWP value of 4 and a similar cooling efficiency. Unfortunately, the R1234yf refrigerant has a significantly lower auto-ignition temperature (around 405°C), which poses a safety concern. Additionally, alternative eco-friendly compounds for car air conditioning systems have been identified. Surprisingly, one of the leading alternatives is carbon dioxide (CO2 or R744), which is classified as a natural refrigerant. CO2 is non-toxic, non-flammable, colorless, inert, and does not negatively impact the ozone layer. However, it places higher demands on the pressures and temperatures within the air conditioning system components.

Production of air conditioning hoses

Individual components of the air conditioning system are connected to different parts of the vehicle's body or engine. As a result, they are subjected to vibrations and movement relative to each other, which requires the use of flexible hoses to connect them. These hoses can come in various sizes and are equipped with suitable mounting flanges. Typically, they consist of a rubber hose with metal ends, often made of aluminum, and various types of connectors that enable their assembly.

The metal end is formed from a tube in order to facilitate its connection with a rubber hose. Mounting blocks are soldered to ensure secure fastening and tightness. A crucial stage of the production process involves bending the aluminum tubes into the appropriate shape, which is determined by the vehicle model, engine type, and other factors. In some cases, the hoses are equipped with heat exchangers to enhance air cooling and reduce the strain on the engine. Once the metal tubes are shaped, a sealant is sprayed onto them, and a vision system is employed to verify the correct application of the sealing layer. The next step involves connecting the metal components with the rubber hose by tightening them with metal clamps.

The rubber used in the hoses should possess the ability to absorb vibrations and ensure a tight connection. Once the pipes are completed, they undergo flow and tightness tests. Achieving tightness is crucial to meet high ecological standards. Therefore, air is pumped out from a special chamber, and helium is injected into the ducts. A spectrometer is utilized to detect any leaks in the system.

Air conditionig tubes & hoses assembly and testing lines by ELPLC

ELPLC has acquired extensive expertise over the years in implementing stands and complete production lines for manufacturers of automotive air-conditioning system components. They provide support for various processes involved in air-conditioning tubes and hoses production, such as induction brazing of aluminum elements, chipless cutting of corrugated steel hoses, TIG orbital welding with electrochemical passivation, clamping, bundle completion, and flow testing. Moreover, ELPLC's lines are equipped with their proprietary ELPLC Smart Factory system, which offers several functionalities. One of its key features is providing access to the complete production history of each component, allowing for detailed analysis. This analysis can be conducted based on various criteria and selected filters, such as efficiency analysis categorized by stations or operators. Additionally, the system allows for data export. More about ELPLC Smart Factory.

Read more: Lines and machines in the production of automotive air conditioning hoses (2)

Footnotes

[1] GWP - Global Warming Potential – is a measure of how much infrared thermal radiation a greenhouse gas added to the atmosphere would absorb over a given time frame, as a multiple of the radiation that would be absorbed by the same mass of added carbon dioxide (CO2). GWP is 1 for CO2. For other gases it depends on the how strongly the gas absorbs infrared thermal radiation, how quickly the gas leaves the atmosphere, and the time frame being considered.

ELPLC SA machines and lines

We specialize in designing and building machines, complete robotic assembly lines and creating software for the industry. We offer our competences for many industries. We provide Industry 4.0 / Smart Factory solutions.

Automation and robotization

Machines and lines building

Modernization fo existing lines

Software for industry

Service and maintenanace

Research and development

Return to blog

Want to know more? Ask experts